Introduction to Coil Testing

An ignition coil is a critical component of the vehicle’s ignition system, responsible for transforming low-voltage power from the battery into high-voltage energy needed to ignite the fuel-air mixture in the engine. If your vehicle is experiencing misfires, rough idling, difficulty starting, or loss of power, testing the ignition coil can help determine if it’s the cause of the issue.

This guide outlines the different methods to test a coil, including visual inspection, spark testing, resistance measurement, and advanced diagnostic techniques.

1. Signs of a Failing Ignition Coil

✅ Engine misfires or rough running – The vehicle may shake or sputter. ✅ Loss of power or acceleration issues – Weak spark results in sluggish performance. ✅ Check Engine Light (CEL) is on – May indicate a coil-related misfire code. ✅ Difficulty starting the car – Weak or no spark can prevent ignition. ✅ Poor fuel economy – Inefficient combustion leads to excessive fuel consumption.

2. Methods to Test an Ignition Coil

Method 1: Visual Inspection

- Turn off the engine and disconnect the battery to avoid electrical hazards.

- Locate the ignition coil and inspect it for cracks, burns, corrosion, or oil contamination.

- Check the wiring harness and connectors for damage or loose connections.

- If visible damage is found, the coil should be replaced.

Method 2: Spark Test Using a Spark Tester

- Disconnect the ignition coil from the spark plug.

- Attach a spark tester to the coil output terminal.

- Ground the tester and crank the engine.

- Observe for a strong blue spark (good) or weak/no spark (bad coil).

⚠ Warning: Never touch the coil while cranking, as it carries high voltage.

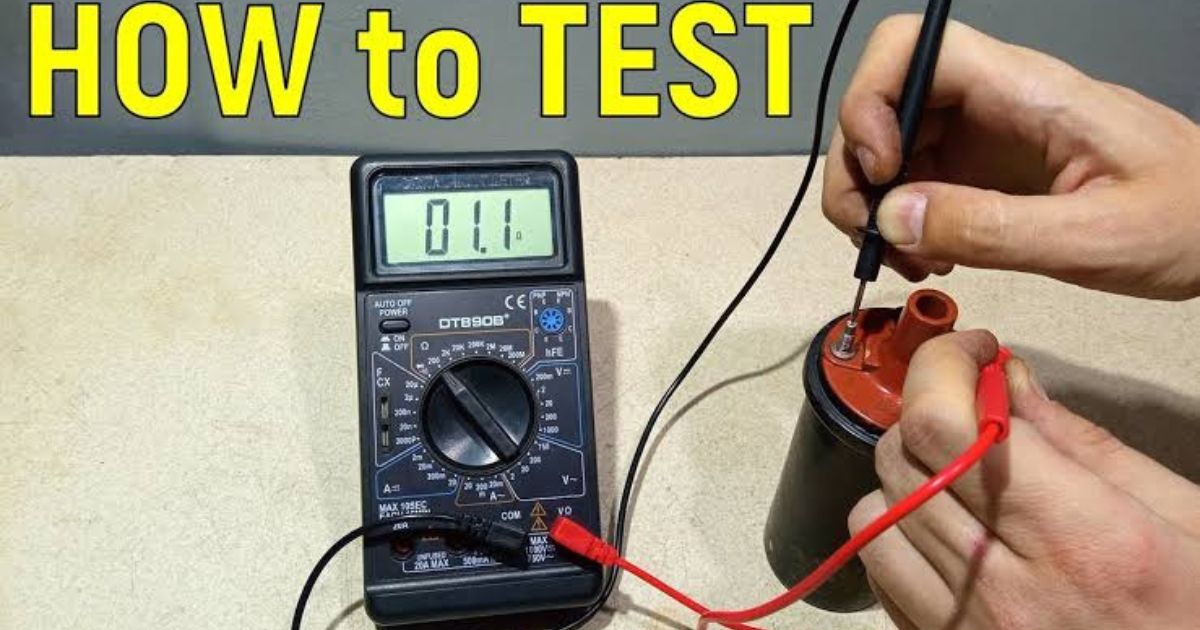

Method 3: Resistance Test Using a Multimeter

- Set the multimeter to ohms (Ω) mode.

- Primary Resistance Test:

- Connect the probes to the positive and negative terminals of the coil.

- A good coil should read between 0.4 – 2.0 ohms (check manufacturer specs).

- Secondary Resistance Test:

- Connect one probe to the coil output terminal (where it connects to the spark plug).

- The other probe should be on the ground terminal.

- A healthy coil typically reads 6,000 – 12,000 ohms.

If the resistance readings are out of range, the coil is faulty and needs replacement.

Method 4: Swap Test for Coil-On-Plug Systems

- Identify the misfiring cylinder using an OBD2 scanner.

- Swap the suspected faulty coil with a known working coil from another cylinder.

- Start the engine and check if the misfire moves to the new cylinder.

- If the misfire follows the coil, the original coil is defective.

3. When to Replace an Ignition Coil

🔹 If the coil fails the spark test or resistance test, replace it immediately. 🔹 If the vehicle has over 100,000 miles, consider replacing all ignition coils preventively. 🔹 Replace spark plugs when installing new coil packs for optimal performance.

4. Preventative Maintenance Tips

🔹 Regularly inspect ignition components for wear and tear. 🔹 Use high-quality replacement coils to ensure longevity. 🔹 Keep coil connectors and wiring free of corrosion or damage. 🔹 Follow the manufacturer’s maintenance schedule for ignition system servicing.

Final Thoughts: Ensuring a Properly Functioning Ignition Coil

Regularly testing your ignition coil can prevent engine misfires, power loss, and starting issues. By following these diagnostic methods, you can accurately determine if the coil is faulty and replace it if necessary, ensuring smooth engine performance and fuel efficiency. If you’re unsure, consult a certified mechanic to avoid misdiagnosis and further vehicle issues.